Final Project Idea

Brief Overview

The three common stages from design to production, on every scale, are design, fabrication, and assembly. As an architect, I have seen design and fabrication tools evolve with time. Assembly has slowly evolved from manual assembly to the current trends of robotic assembly. The evolving field in the direction of assembly is Self- Assembly of macroscopic(visible with naked eye) scale. Though the reality of self-assembly (can be defined as a process by which preexisting components (Bseparate or distinct parts of a disordered structure) isn't new, it is the fundamental process by which DNA/RNA self-replicate and self-assemble. RNA/DNA do not have the manual tools like we do assemble or replicate themselves. Hence, for my final project, I got inspired by the work of Skylar Tibbits and would like to create Self-assembling lattice structure. It would be an uphill task considering the amount of time left but part of the journey is the fun.

What it will do?

Self-assembly is more like joining pieces of the puzzle, only that you don't have to manually do it, it can do it on its own. In my project you only have to design and make individual modules and think about a final configuration/shape/form. One can also imagine self-assembly as an important aspect in the proceess of building any product which consists of lot of components, you then have to only make the components which will self assembly themselves into a final product lets say a modular table or a shelf.

Who has done what beforehand?

Skylar Tibbits from MIT runs Self-Assembly Lab, where for several years he has been working on self-assembly and programmable matter. He has made several artifacts based around it. The ones useful for me are Fluid Assembly Chair and Skylar's graduate thesis called Logic Matter. Fluid Assembly Chair includes three key aspects of self-assembly: geometry(design), interaction and energy(for activation). His thesis talks about embedding digital information into material parts to provide self-guided assembly of complex structures.

Ariel Ekblaw also from MIT, while pursing "How to make almost anything" few years ago made a self-assembly buckyball for zero gravity. She used magnet joined tiles for self-assembling space architecture.

L.S.Penrose' principles published in Scientific American led to the development of mechanical latching system for self-assembly.

Who doesn't loves open-source projects, a slightly different kind of self-assembly(as well as self structuring) project is put forward by Paul Clemens Bart called noMad . He created individual modules that itself can change form and grow in size to some extent while interacting with other modules. Modules have self-aware unit to unit communication instead of a deterministic, superimposed building plan.

A paper on Self-Assembly at the Macroscopic Scale by Roderich Groß and Marco Dorigo discusses about externally propelled self assembly components, where I am interested in as well as self propelled self assembly components. This paper is probably the most helpful one with lot of data on dimentions, weight, DOF of individual modules used for self-assembly.

Since there is no known algorithm for self-assembly at macro scale, I had to look up for a paper that talks about it. Meshing complex macro-scale objects into self-assembling bricks by Adar Hacohen, Iddo Hanniel, Yasha Nikulshin, Shuki Wolfus, Almogit Abu-Horowitz and Ido Bachelet describes an algorithm inspired by the molecular assembly of DNA, and based on bricks designed by tetrahedral meshing of arbitrary objects.

Who will use it?

There is no limit to who can use this, if one is planning to make a product, one can incorporate it as the part of manufacturing process.

How?

Few ways to create self-assembly structures are:

1. Reconfigurable robots being one of them that involve large amount of electromechanical parts. It would be really hard for me to do this within this short amount of time. This field has now evolved itself into programmable matter and could be explored in detail someother time.

Reconfigurable self assembly robots

2. Another method that I found very useful is Stochastic Modular System method, that involves individual modules being agitated by an external source(could be fluid or air or a tumbler rotated at a certain speed) to propel them. This method particularly involves hit and trial such that it gives individual modules enough time to get close and attach themselves to another module.

The above video illustrates using a tumbler that is spun to create an external energy for modules to get closer and interact with each other. This is Stochastic Modular method.

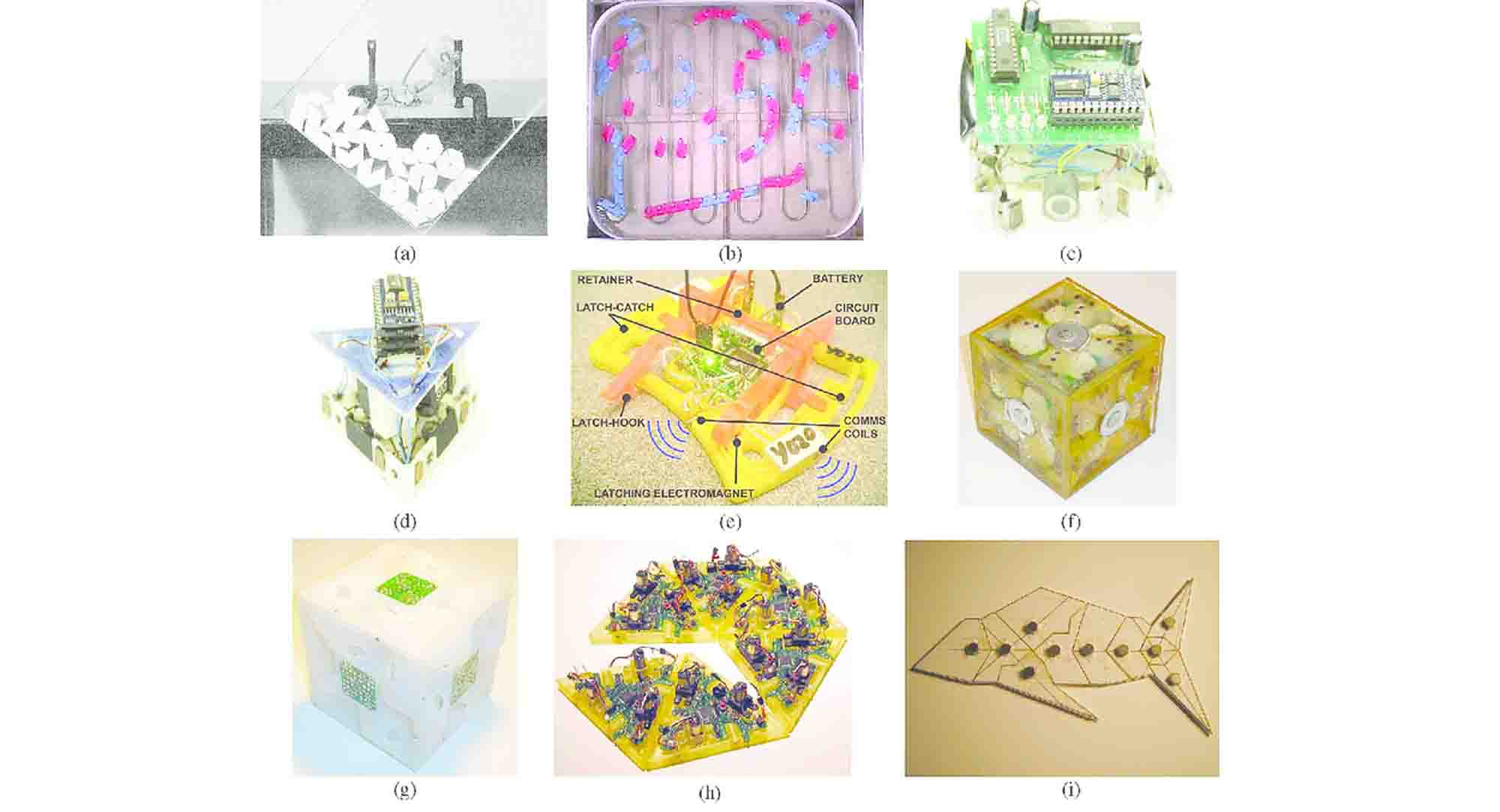

Systems with externally propelled components: (a) Hosokawa et al.’s self-assembling hexagons (reprinted by permission fromMIT Press: Artificial Life [57]). (b) Breivik’s template-replicating polymers [12] (photo courtesy of J. Breivik, University of Oslo).(c), (d) White et al.’s self-assembling programmable modules (photo courtesy of P. J. White et al., Cornell University). (e) Griffith et al.’selectromechanical assemblers [reprinted by permission from Macmillan Publishers Ltd: Nature [43], copyright (2005)]. (f) White et al.’s firstsystem for self-assembly in 3-D (photo courtesy of P. White and H. Lipson, Cornell University). (g) White et al.’s second system for self-assembly in3-D (photo courtesy of P. White et al., Cornell University). (h) Programmable parts testbed (photo courtesy of E. Klavins, University ofWashington). (i) Bhalla and Bentley’s self-assembling special purpose modules (photo courtesy of N. Bhalla and P. J. Bentley,University College London).

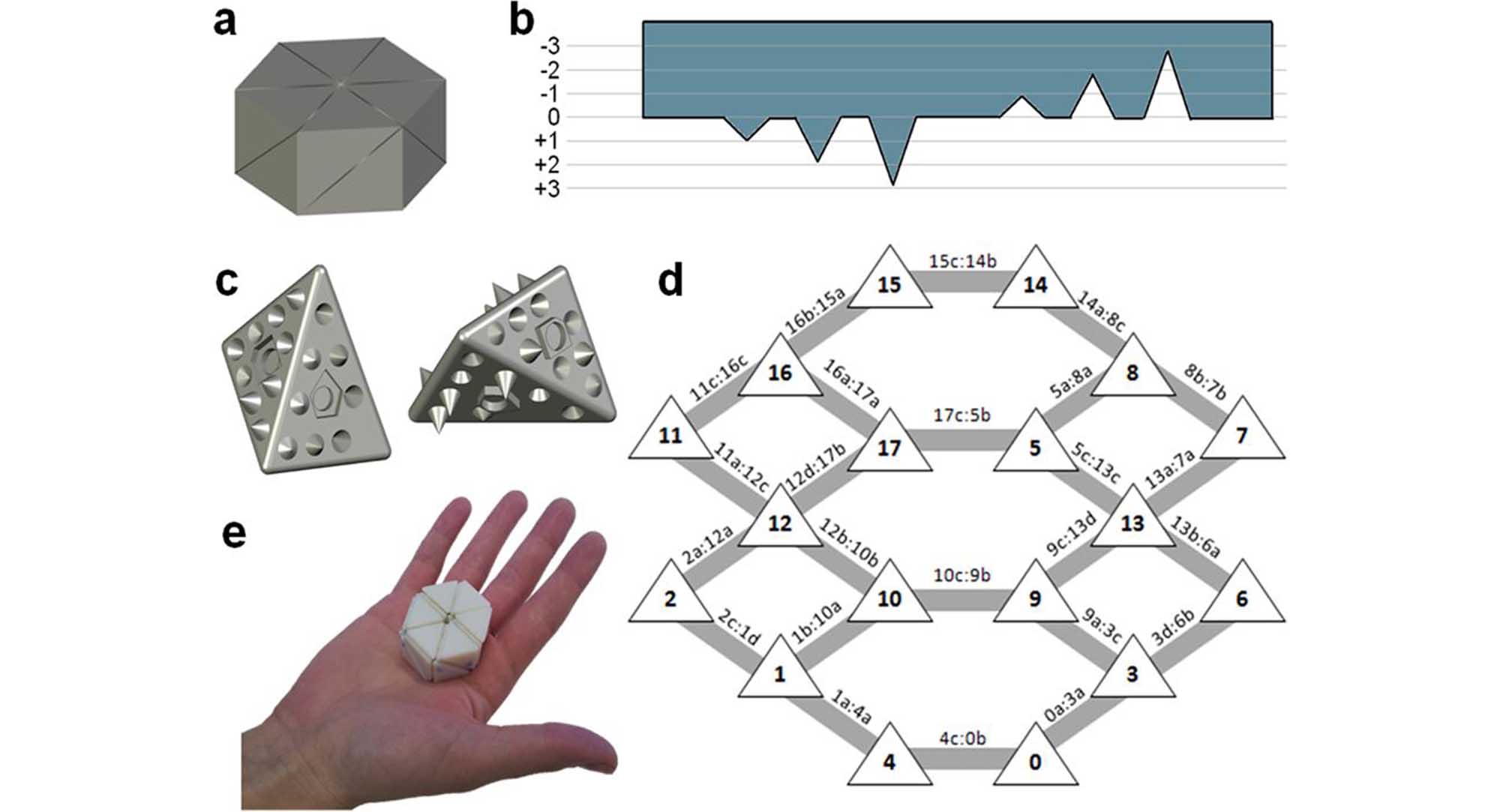

Object and brick design and fabrication. (a) The prototype assembly object, a cylinder with radius and height of 15 mm. Delaunay tessellations resulted in a subdivision of the polygon into 18 tetrahedrons from 3 different types. (b) Schematic representation of conical cue heights. There are 7 different heights: –3.0, –2.0, –1.0, 0, + 1.0, + 2.0 and + 3.0 mm. (c) A tetrahedral brick (number 13) from 2 different views. Each face has a unique topography. Our topography design consists of 10 cues per face. The nine peripheral cues are conical. The central cue can have two different pentagon shapes and two different heights: + 1 or − 1. In the central cue there is an additional round cue, in which a permanent disc magnet is embedded. (d) A graph describing the whole object composed of its building bricks. Each node represents a brick and each edge represents a face-face interaction between 2 bricks. Out of all 18 bricks, there are 2 bricks that interact via all 4 faces, 8 bricks that interact via 3 faces and 8 bricks that interact via only 2 of their faces. (e) The final object printed and assembled.

The way forward

Many people starting from John von Neumann and LS Penrose gave theoretical insights on self replication and self assembly. They have given us principles and methods for self-aseembly. The recent work and papers published have really helped me in understanding self-assembly through stochastic method. Moving forward, I will focus on the design of modules, creating an algorithm for the interaction and negotiation between modules and electronics design, particularly networking and communication between modules. I intend to think that this step though inspired by the previous works done by many people will help me in creating something that will be openfor improvement.